Medium Duty, Swivel Easy-Turn Plate Caster with Pneumatic Wheels; 1250 lb. Load Rating, 12" Wheel Dia.

#925493Pkg Qty: 1

In Stock

Technical Specifications

Key Specifications

General

Product Description

Super-duty easy-turn plate casters each have two pneumatic wheels mounted on a single axle. This reduces friction between the floor and the wheels (also known as scrubbing), which allows the casters to swivel more easily than single-wheel plate casters. The casters have thick steel frames and heavy-duty bearings and can bear more weight, withstand rougher terrain, tolerate higher speeds, and absorb more shock and impact than other types of plate casters with pneumatic wheels. The casters' pneumatic wheels have air-filled tires that provide cushioning when transporting electronics and other loads that are sensitive to shock and vibration. Super-duty plate casters with pneumatic wheels are suitable for use on heavy carts, trucks, and other equipment used in indoor or outdoor towing applications over rough or uneven terrain, such as aerospace ground support, manufacturing sites, and shipping operations.

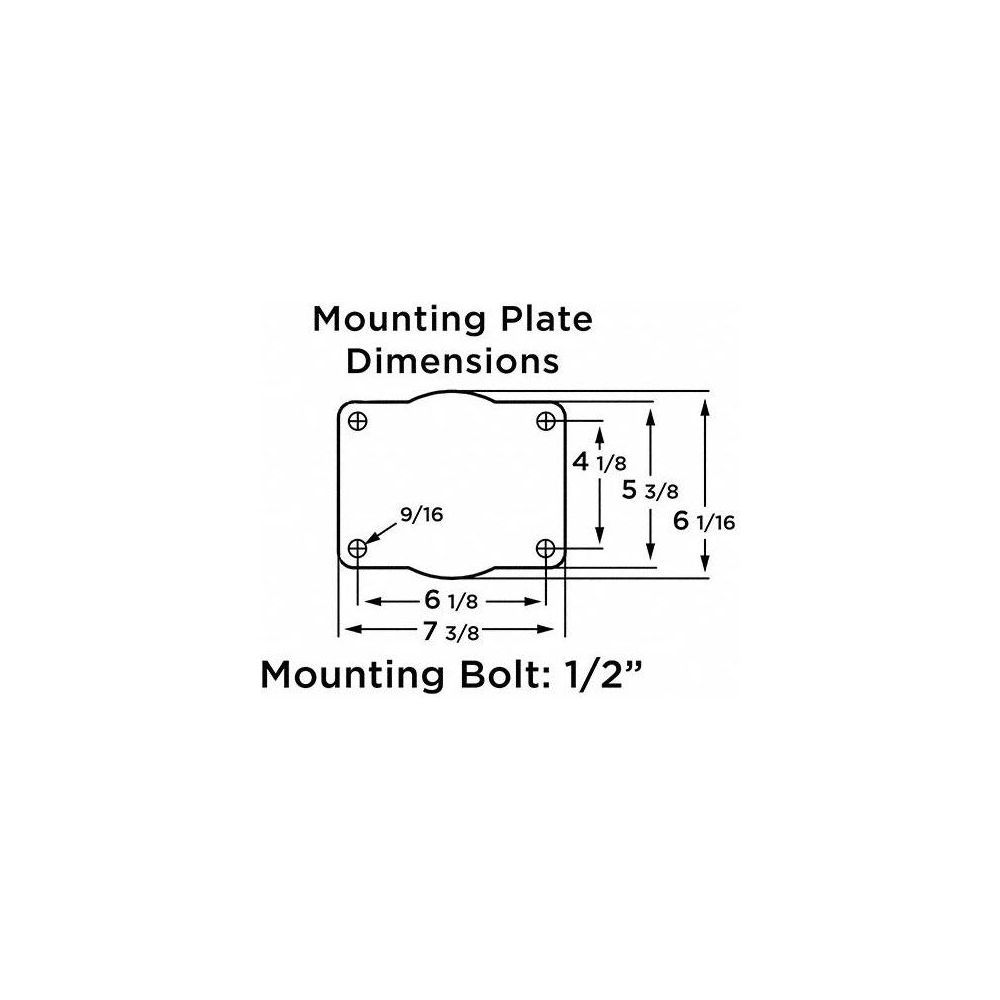

Smooth-ride pneumatic, semipneumatic, and flat-free plate casters have air-filled, foam-filled, or solid-rubber caster wheels that allow them to absorb more shock and vibration, provide more stability, and produce less noise than other types of plate casters. These casters are suitable for transporting fragile or vibration-sensitive loads and for moving loads over rough or uneven surfaces in outdoor areas and industrial facilities. The casters have a mounting plate that mounts onto the bottom of carts and other equipment to allow the equipment to roll, reducing the effort it takes to move or reposition the equipment. They come in swivel and rigid versions. The swivel casters can rotate 360°, allowing equipment to change directions while rolling. The rigid casters roll in a straight line. Two rigid plate casters can be paired with two swivel casters to allow the equipment to both maneuver around curves and obstacles and maintain a straight course while rolling.

Item Barcode

For more product information by email, click here

Abrasives

Abrasives Air Brake

Air Brake Assortments

Assortments Building & Grounds

Building & Grounds Chemicals

Chemicals Cutting & Holemaking Tools

Cutting & Holemaking Tools Electrical

Electrical Fasteners

Fasteners Fluid Transfer & Pumps

Fluid Transfer & Pumps Furniture & Office Supplies

Furniture & Office Supplies Hardware

Hardware Hose & Hose Ends

Hose & Hose Ends HVACR

HVACR Hydraulics

Hydraulics Janitorial

Janitorial Lighting

Lighting Material Handling

Material Handling Paint & Paint Supplies

Paint & Paint Supplies Pipe, Tubing & Fittings

Pipe, Tubing & Fittings Plumbing

Plumbing Pneumatics

Pneumatics Power Transmission

Power Transmission Safety

Safety Steel Equipment & Storage

Steel Equipment & Storage Tape

Tape Testing & Inspection Tools

Testing & Inspection Tools Tools

Tools Vehicle & Trailer Parts

Vehicle & Trailer Parts Welding

Welding Wheel & Tire

Wheel & Tire